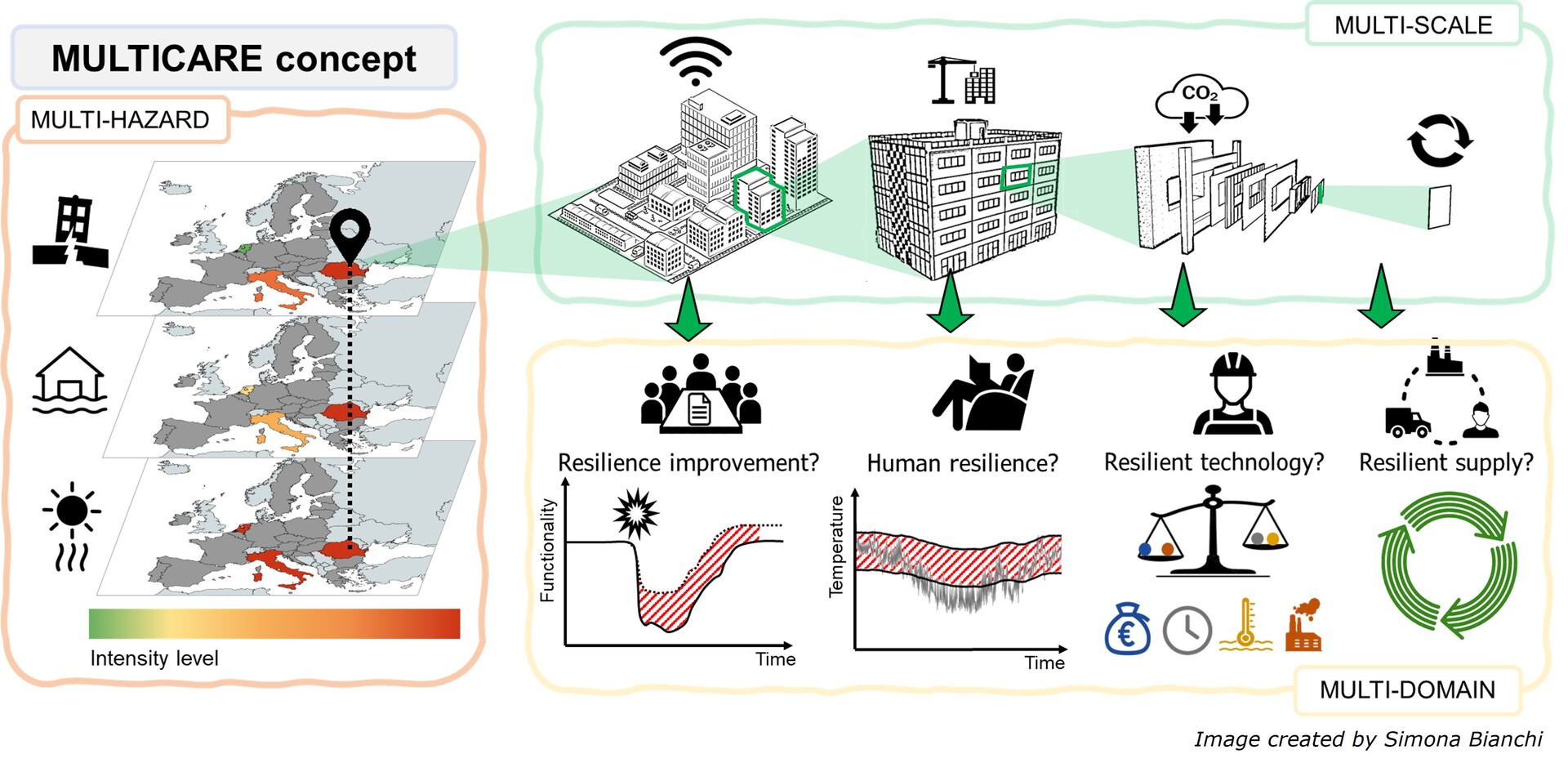

MULTICARE

Multi-hazard low-carbon resilient technologies and multi-scale digital services for a future-proof, sustainable & user-centred built environment.

The built environment is ill-prepared for more frequent and increasingly intense climate-related extreme events. These cause severe socio-economic losses and adversely affects public health. Recent scientific and technological advances in the construction industry provide timely solutions for improving the resilience of buildings for specific hazards, but these are often not cost effective or eco-friendly. There is a lack of frameworks for assessing the climate resilience, making it challenging to develop optimal solutions for multi-hazard scenarios.

Project Leader: Prof. Mauro Overend, Dr. Simona Bianchi | Research Team: Dr. Alessandra Luna-Navarro, Dr. Azarakhsh Rafiee, Prof. Peter van Oosterom, Dr. Thaleia Konstantinou | Period: 2024 - 2028 | Budget: € 1.200.147,31 | Funded by: European Union: Horizon Europe

DATALESs

Data-driven green building modelling, energy management & building cluster federation

Integration of a large number of distributed energy resources (DERs), such as distributed wind and PVs systems as well as the increasing electrification of the heating and transport sector poses great challenges on distribution and transmission network operation. In this situation, local energy systems (LESs) and green buildings open up new possibilities to utilize local, renewable energy sources in a decentralized way as well as to provide operational support. However, their role and potential in urban areas are, yet, underdeveloped. Here, a major challenge is how to integrate the thousands of controllable elements in LESs and green buildings into traditional control or optimization frameworks while still guaranteeing optimal system-level objectives. In line with this, we aim to develop a new data-driven operational paradigm for LESs from cyber-physical-societal perspectives, with a special focus on DERs integration, LESs and green building flexibility exploring, and actor integration. The project comprises six Work Packages. TUDelft-BK is involved in WP3 (Data-driven green building modelling and energy management). The main tasks within this WP include data-driven modelling of green building, physics-integrated machine learning for building energy management, federation and coordination of building cluster energy information and design of energy saving scheme based on field lab validation.

Project Leader: Dr. Ing. Thaleia Konstantinou | Research Team: Prof. dr. ir. Peter van Oosterom, Dr. Azarakhsh Rafiee | Period: 2022 - 2026 | Budget: € 290.328 | Funded by: NWO-NSFC

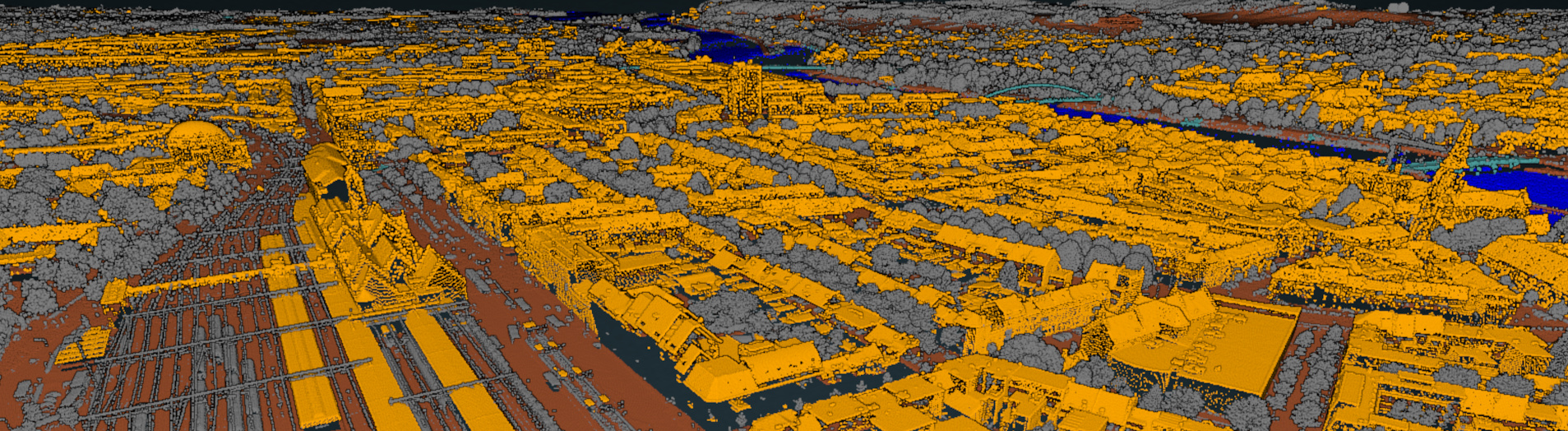

nD-PC Multi-dimensional Point Clouds

The main challenge in this proposal is to realize a distributed Open Point Cloud Map (OPCM) scalable infrastructure with High Performance/Throughput Computing (HPC/HTC) and enable interactive visualization using perspective views without data density shocks, continuous zoom-in and out and progressive data streaming between server and client.

Big geo-data requires good spatio-temporal data organization, including levels of detail that allow to zoom in from high-level overviews (complete countries/continents) to the smallest detail (as the curb stones of a sidewalk) and everything in between. The world’s largest point cloud data sets, despite their potential high value, are heavily underexploited due to the problematic data management, access, and limited software tools that are able to directly employ them. This project aims to realize the paradigm shift from raster and vector representations to the new, highly efficient, nD-PointCloud representation with deep integration of space, time, scale/continuous Levels of Importance (cLoI) dimensions.

Project Leader: Prof.dr.ir. P.J.M. (Peter) van Oosterom | Research Team: dr. Vitali Diaz Mercado, Prof.dr.ir. Peter van Oosterom, dr.ir. Martijn Meijers | Period: 2022 - 2025 | Budget: € 253.000 | Funded by: Netherlands eScience center (by SURF & NWO)

Wood Without Trees Research Project

Wood is typically a well-recognized option by society, and the widely available processed timber presents remarkable properties. However, its use comes with drawbacks related to excessive waste from conventional subtractive fabrication processes, need of adhesives (which are often toxic or based on fossil resources), and difficulties in the fabrication of complex geometries. The strength of wood derives from its building blocks (lignocellulosic fibres), which are the most abundant biopolymers in nature. Cellulose is commonly used as raw material in the paper industry and as a fibre reinforcement on bio-based composite. Lignin is a by-product from the same industry, usually burnt as an energy source. They can be extracted from several waste streams, including agricultural and forestry waste. When combined, they can create a fully natural material with similar characteristics to timber but with potentially adjustable mechanical properties and more freedom to generate complex structures. The on-going Wood Without Trees project studies a solution to upcycle both components into a fully biobased material for additive manufacturing. The project aims to be a stepping stone toward full circularity (from locally sourced bio-waste streams to material recyclability within the construction industry) while allowing for easy to tune material properties and high-performance building components thanks to 3D printing – and thereby resulting in reduced greenhouse gases emissions and waste.

Project Leader: Dr. MSc.Arch. M. Turrin

3D Land Administration

In the past decade various activities have been conducted related to 3D Cadastres. The start of the international awareness of this topic was marked by the first Workshop on 3D Cadastres (sponsored by FIG commissions 3 and 7), organized by Delft University of Technology in November 2001. This was followed by virtually a session at every FIG working week and congress afterwards (stimulated by the 2002-2006 FIG working group on 3D Cadastres). Within cadastral organizations this was paralleled by on-going developments at Cadastral organizations in many countries to provide better 3D-support. The increasing complexity of infrastructures and densely built-up areas requires a proper registration of the legal status (private and public), which only can be provided to a limited extent by the existing 2D cadastral registrations. Despite all research and progress in practise, no country in the world has a true 3D Cadastre, the functionality is always limited in some manner; e.g. only registering of volumetric parcels in the public registers, but not included in a 3D cadastral map, or limited to a specific type of object with ad hoc semi-3D solutions; e.g. for buildings or infrastructure. At the FIG Congress in April 2010 in Sydney it was decided to form again a working group on 3D Cadastres in order to make further progress with the subject. The registration of the legal status in complex 3D situations will be investigated under the header of 3D Cadastres. Starting point of the working group is the observation that increasingly information is required on rights, use and value in complex spatial and/or legal situations.

IEBB - Theme 4: Digitizing the Renovation Process

Project 4.3: 3D Printing & Logistics

The goal of this project is to develop an automated process to optimize and manufacture building components enabling passive design toward energy transition. The process involves the parametric generation of multiple design configurations optimized for minimal energy consumption and allows the end user to select a custom solution. Starting with a digital model of existing buildings, the process includes parametric design, optimization, and 3D printing using artificial intelligence. Furthermore, in this project concepts are developed and demonstrated (e.g. sunshading and trombe walls), which illuminate the entire process from parametric optimization to user preferences and final production.

Research Team: Özgün Balaban (Post Doctoral Researcher), Sevil Sariyildiz, Martin Tenpierik, Thaleia Konstantinou, Serdar Asut, Paul de Ruiter, Michela Turrin | Partners: TU Eindhoven, VolkerWessels, ESTECO SPA, Arup bv, TU Delft, Royal 3D, Saint Gobain | Period: 2020 - 2021

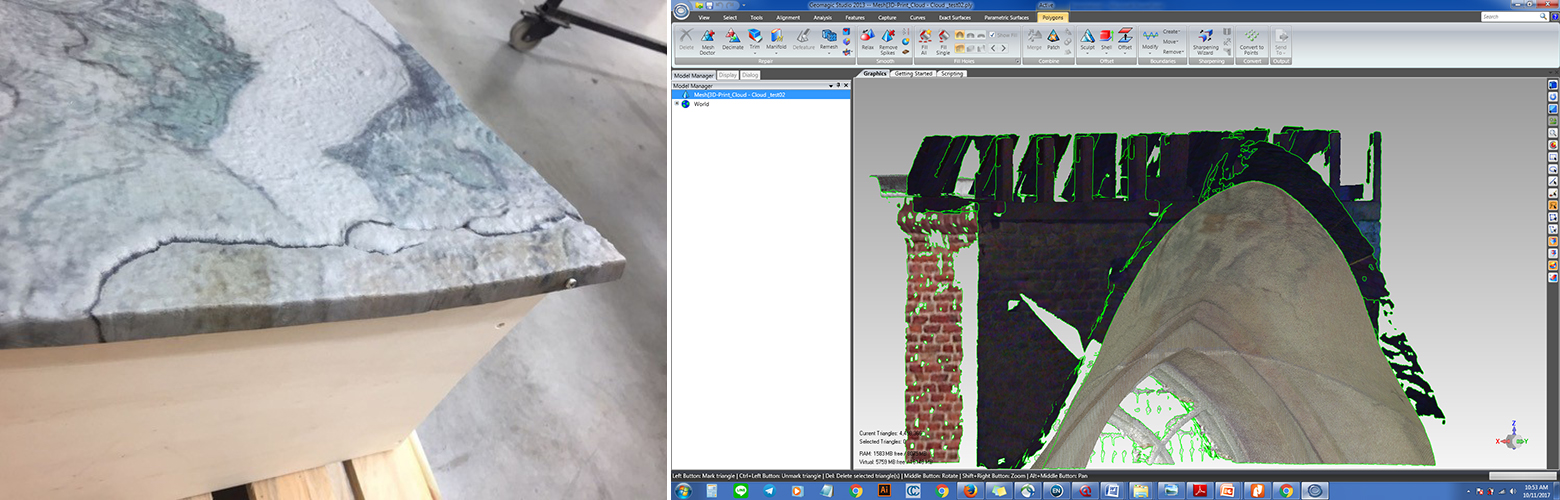

Reprinting Architectural Heritage – 4TU Lighthouse project

As scientists in private and public settings develop new technologies for 3D scanning and 3D printing at the scale of paintings, ornaments, building parts, they encounter questions related both to technical possibilities and usability of 3D printing at the scale of the building with high resolution. We are convinced that these developments can propel technological, heritage and architectural design discussions forward in each field and in connection to each other. We propose a pilot that includes high-definition scanning and 3D printing of a pilot structure, the Hippolytuskerk Middelsum, at a building scale that challenges high-precision 3D printing developed for paintings to take on the building scale, its multiple dimensions and materials, and to connect to heritage specialist and designers to rethink the applicability of the new technique in academia, practice and education.

Project Leader: Prof. dr. ir. Carola Hein | TU Delft Research Team: ir. John Hanna, ir. Miktha Farid, Dr. Serdar Aşut, Dr. M. Turrin, Prof.dr.ing. C. Hein, Prof.dr. Joris Dik | TU Eindhoven Research Team: Prof.ir. J. Bekkeringet al | Partners: 4Visualisation (ing V. Vanhecke), KIWI Solutions (Dick Vlasblom), Stichting Oude Groninger Kerken | Period: January 2017-March 2018 | Budget: € 50.000 | Funded by: 4TU Centrel of Excellence for the Built Environment

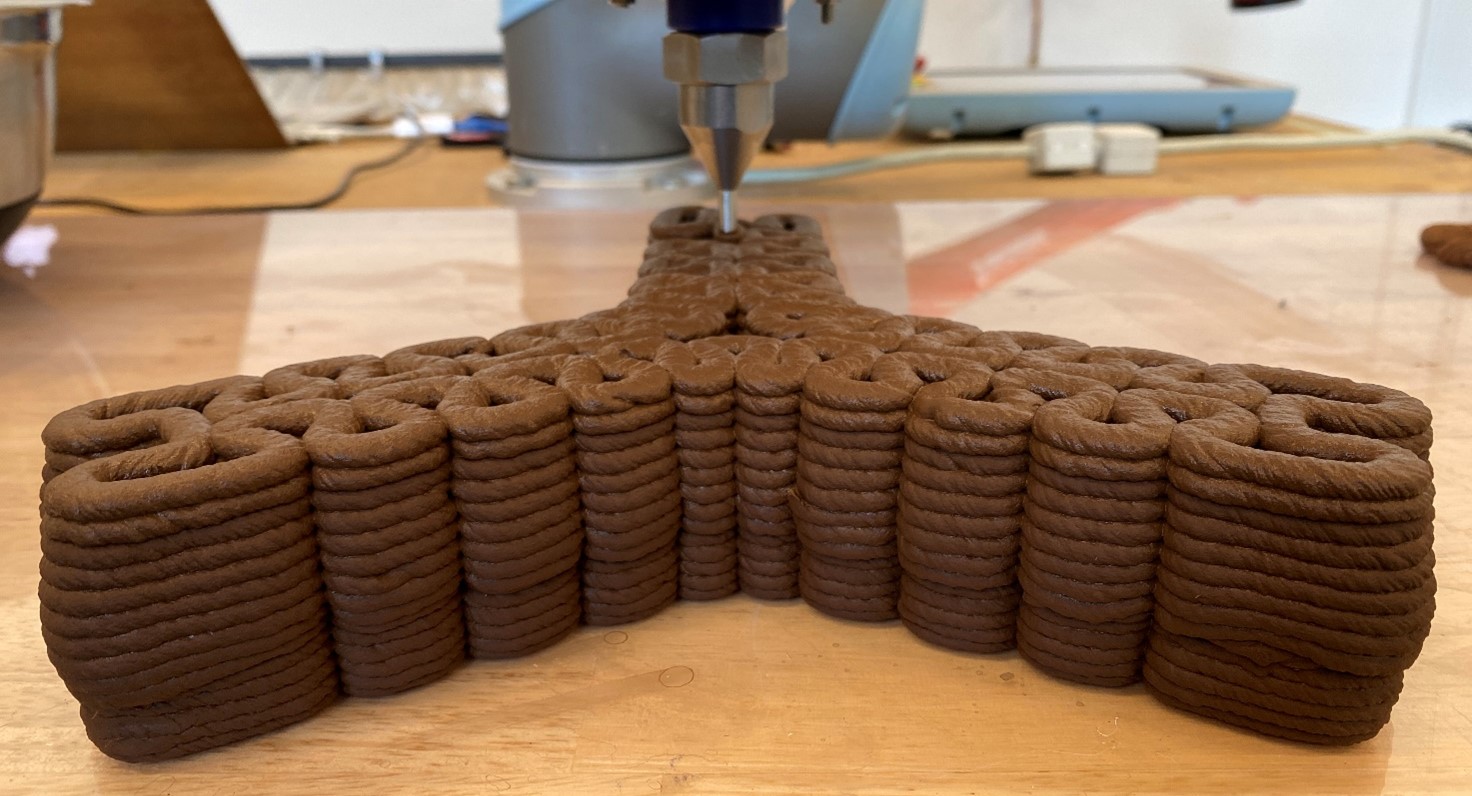

TERRA-ink - 4TU Lighthouse Project

TERRA-ink aimed at developing a method for layering local soil, by implementing 3D printing technologies. With the aid of such a construction system, the goal was to create durable structures that can be easily de-constructed once they served their purpose. The use of locally sourced materials in combination with additive manufacturing is investigated aiming at reductions in financial investments, resources and human labor, as well as at simplified logistics, low environmental impact and adaptability to different situations and requirements. Such a building system has the potential of combining low and high-tech technologies, in order to facilitate a fully open and universal solution for large scale 3D-printing using any type of soil.

Project Leader: Dr. MSc.Arch. M. Turrin / Main Researcher: ir. Tommaso Venturini / TU Delft Research Team: Dr. MSc. Arch. Michela Turrin, MSc. Arch. Foteini Setaki, Dr.ir. Fred Veer, Ammar Taher / TU Eindhoven Research Team: ir. A.D.C. (Arno) Pronk, prof. Dr. ing. Patrick Teuffel, Yaron Moonen, Stefan Slangen, Rens Vorstermans / Period: January 2017-March 2018 / Budget: € 50.000 / Funded by: 4TU Centrel of Excellence for the Built Environment

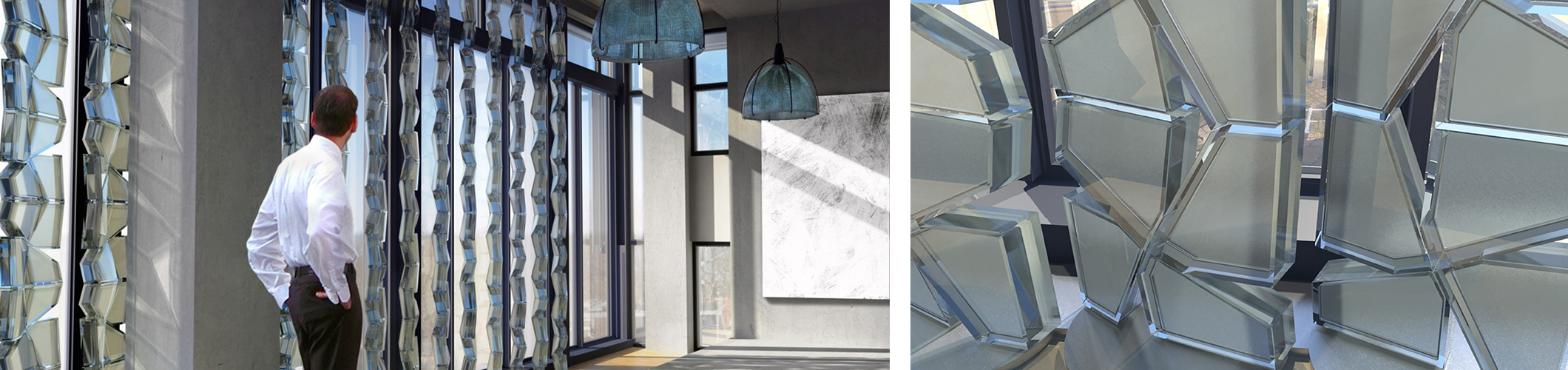

DoubleFace2.0 – Research Through Design NWO project

Double Face 2.0 is a novel solar wall, joining a strong design identity and high technical performances. During the Double Face 2.0 project thermal, daylight and manufacturing performance aspects were such design drivers in the development of an innovative lightweight translucent Trombe wall (solar wall). The proposed wall overcomes the limitations of traditional Trombe walls, which are usually massive and obstructive. It uses new materials like phase change material (PCM) for heat storage and aerogel for thermal insulation, has an optimised shape for best thermal performance, is manufactured using robotic 3D (FDM) printing, allows daylight to pass through and can be adapted according to the varying conditions at hand. By optimising and shaping geometry, the final design has good engineering performance and at the same time offers new creative opportunities for the designers.

Project Leaders: Dr.ir. M.J. Tenpierik, Dr. MSc.Arch. M. Turrin | Research team: Stavroula Tsafou MSc, Tudor Cosmatu MSc, Ir. Yvonne Wattez, Dr.ir. Martin Tenpierik, Dr. MSc.Arch. Michela Turrin | Partners: GlassX, Esteco, Rubitherm, Arup, Shau Architecture and Urban design | Period: 2016-2018 | Budget: € 268.000 | Founded by: Technology Foundation STW NOW

Spong3D – 4TU Lighthouse project

This research investigated the potentials of Additive Manufacturing porous structures for thermal performances, and more specifically thermal insulation and heat storage. It focused on the potentials of AM for an adaptive facade system that optimizes thermal performances according to different environmental conditions. The main general objective was is to prove that AM 3d printing technology enables the creation of mono-material façade components that integrate multiple functions. The specific objective was to create a plastic façade panel that can regulate the temperature inside a building throughout the whole year. It used the thermal properties of porous structures and the heat storage capacity of liquids. The final product is a proof of concept for an adaptive façade panel that controls the heat exchange between the indoor and the outdoor environment by integrating geometries for thermal insulation and heat storage, while guaranteeing structural strength.

Project Leader: Dr. MSc. Arch. M. Turrin / Main Researcher: ir. Maria Valentini Sarakinioti / TU Delft Research Team: ir. Maria Valentini Sarakinioti, Dr. MSc.Arch. M. Turrin, Dr.ir.arch. MJ.Tenpierik, Dr.Ing.MSc.T.Konstantinou, Prof.dr.ing.U.Knaack, MArch.M.Teeling, ir.P.de Ruiter, ir.M.vanErk / TU Eindhoven Research Team: MSc. M.L. de Klijn, ir.A.D.C. Pronk, prof.Dr.-Ing. P.M.Teuffel, A.J.van Lier, R.L.G.Vorstermans, E. Dolkemade, prof.dr.ir. J.L.M. Hensen, ir. R.C.G.M. Loonen / Partners: Dick Vlasblom (KIWI solutions) / Period: January 2016-January 2017 / Budget: € 50.000 / Funded by: 4TU Centrel of Excellence for the Built Environment

ADAM - Open Technologieprogramma NWO

Existing absorption technologies are strongly limited by traditional materials, design and production processes and consequently do not cover the increasingly required demand in customization, optimized performance and complex shapes. ADAM explores the merging of the academic and industrial fields of Room Acoustics, Additive Manufacturing and Parametric Modelling. A new cutting-edge acoustic device is proposed that regulates its performance by its geometrical characteristics based on interference principles. The developed absorbers are easily customizable and point towards new acoustic structures with highly tuned performance and increased freedom in design and material choice.

Project Leader: Prof.dr.ir. Arjan van Timmeren | Research Team: Ir. Foteini Setaki, dr. ir. Fengnian Tian, dr.MSc.Arch. Michela Turrin, dr.ir. Martin Tenpierik, Prof.dr.ir. Arjan van Timmeren | Partners: Arup, Merford, Materialise, Peutz | Period: January 2015 – December 2018 | Budget: € 570.000 | Funded by: NWO

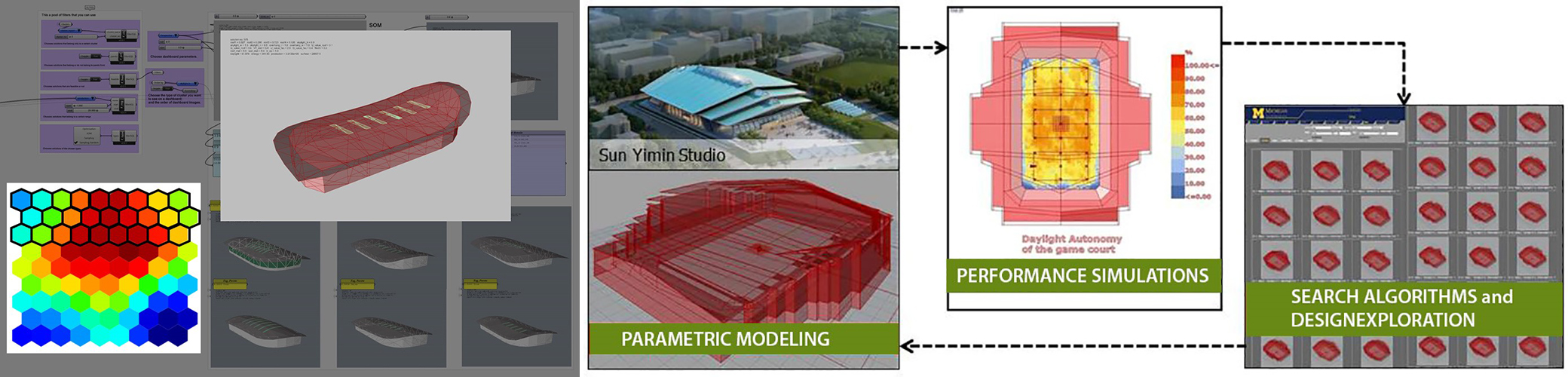

Computational Design for Sport Buildings

The design of sport buildings has great impact on top-sport as well as on recreational sport-activities. The project deals with the concept of Multi-objective Multidisciplinary design optimization techniques to support trade-off decisions between multiple conflicting design objectives and interdisciplinary design methodology, during the conceptual design of sport buildings. The proposed method is based on parametric modelling, performance simulation tools and algorithms for computational optimization, for which the project tackles three specific aspects. Firstly, variable screening techniques are investigated to refine the design space before running the optimization, and thus make the optimization more efficient and feasible within the limited time-frame of real projects. Secondly, a customized computational process for the rapid assessment of temperature and airflow patterns is developed. Thermal and daylight objectives are combined with structural optimization. Thirdly, the process requires the combination of design optimization and design exploration, while searching for well-performing solutions, for which multivariate analysis algorithms are engaged into the post processing of numerous optimization data.

Project Leader: Dr. MSc.Arch. M. Turrin | Research Team: ir. Antonio D'Aquilio, ir. Rusne Sileryte, ir. Ding Yang, ir. Pan Wang, Dr. MSc.Arch. M. Turrin | Partners: SCUT, Arup, ESTECO | Period: 2014-2016 | Budget: € 35.000 | Funded by: TUDelft Sport Engineering Institute and TUDelft-SCUT USE

DoubleFace – 4TU Lighthouse Project

Goal of this project was designing and prototyping an adjustable translucent modular system featuring thermal insulation and thermal absorption in a calibrated manner. Specifically, the project designed and prototyped a modular system for adjustable translucent thermal mass, based on an innovative (digital) approach to thermal principles of trombe walls. Effort was addressed especially towards lightweight options for thermal inertia. The system aimed at passively improving thermal comfort. The project outputs provided a test case and demonstrator of the design principles.

Project Leader: Dr. MSc.Arch. M. Turrin | Research Team TUDelft: Dr. MSc.Arch. M. Turrin, Dr.ir. M.J. Tenpierik, Ir. C. Chang, Ir. P. de Ruiter, Ir. W. Meijer, Ir. W.H. van der Spoel | Resrarch Team TUEindhoven: - Dipl.-ing. F. Heinzelmann, Prof. dr.-ing. P. Teuffel, Ing. W. van Bommel | Period: July 2014 – Feb. 2015 | Budget: € 50.000 | Funded by: 4TU Centrel of Excellence for the Built Environment